| Roll & Sheet | |

| Alloy | 1050, 1060, 1070, 1200, 1235, 3003, 3103, 3105, 3004, 5005, 8011, 8006, 8111 |

| Condition | H0, H12, H22, H14, H24, H16, H26, H18, H28 |

| Thickness | 0.25-4mm |

| Maximum Width | 1250mm |

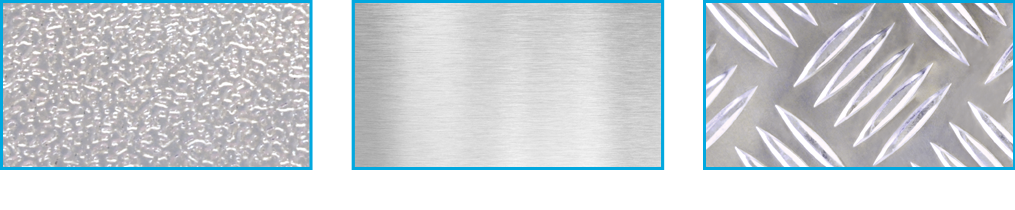

| Surface | Tread, Embossed, Straight |

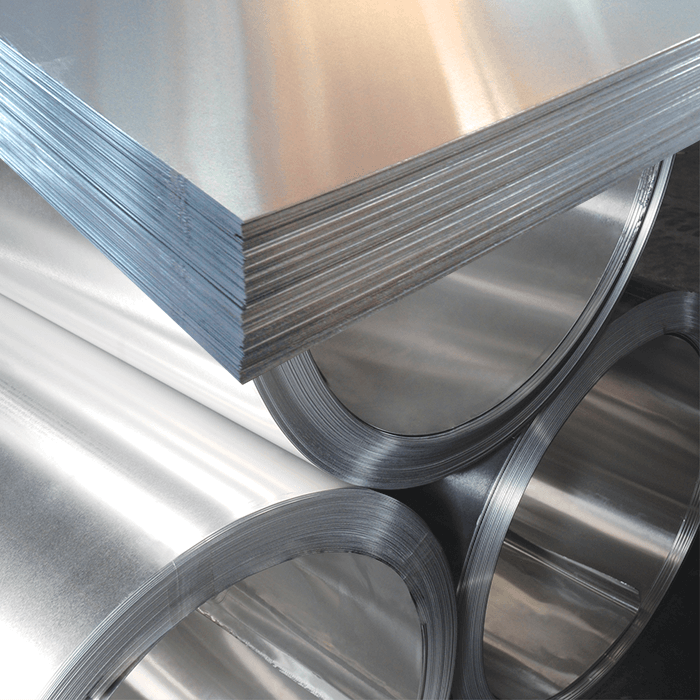

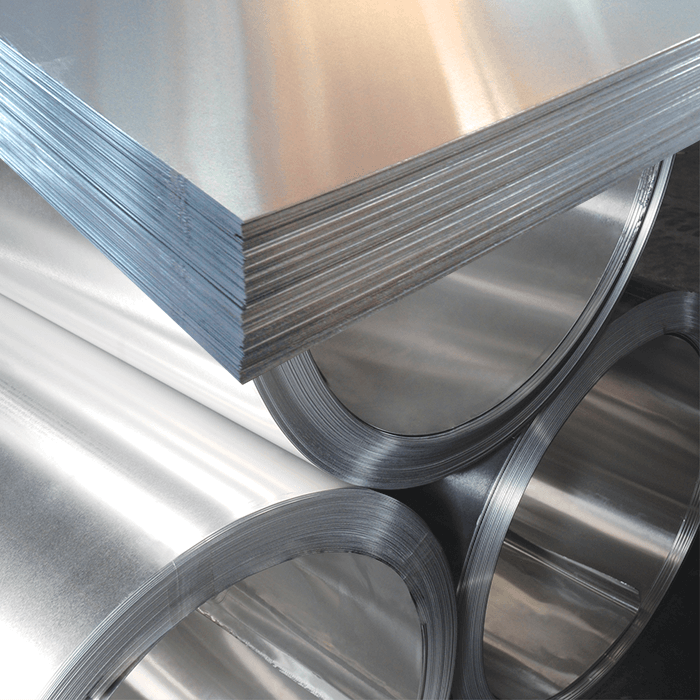

As Selçuklu Konalsan, our factory produces strip sheets and rolls in width and thickness suitable for customer demand, with the capacity to produce sheets and coils with a maximum width of 1250mm up to 0.25mm-4.00mm.

Aluminum Sheet

The industrial product obtained by rolling aluminum materials is called aluminum sheet. Aluminum sheets can be easily processed and those produced in thin form are called sheet metal, and those produced as thick are called plates.

Aluminum

Aluminum is one of the most abundant elements in nature and it is one of the most used materials in a wide sector network with its low weight and stainless feature. Since pure aluminum in nature has low durability, it can be shaped and made more usable by alloying it with more durable materials.

Aluminum Sheet Features

Aluminum element can be used in many areas because it has high resistance to deterioration. It provides the opportunity to process the surfaces of aluminum sheets. Prints and colors can be applied on the plates, as well as many motifs, especially embossed and cutlery. Since it is resistant to processes, it offers the opportunity to join easily by welding.

Since aluminum is not heavy, it takes shape faster than steel castings and provides the opportunity to use the tools used without difficulty by reducing the failure rate. With the coatings to be applied to the aluminum plates, the surface hardness can be increased even more and it can be brought closer to the hardness level of the steel.

Since aluminum sheets have low weight and density, they provide savings in easy transfer, packaging and maintenance operations. Aluminum sheets can also be produced in plate shapes such as rolls, bars, pipes and profiles.

Since aluminum has the opportunity to be reprocessed, it is a material that contributes to nature and recycling by being produced again without any decrease in the quality of each product produced.

Usage Areas of Aluminum Sheets

- The thin ones of aluminum sheets are preferred in sectors such as advertising, machinery and energy, and the thick ones are preferred in the mold and machinery sectors.

- It is used a lot in the production of vehicles such as airplanes, ships, cars, because it allows them to have a lower weight, to be durable for many years with their stainless feature, and to save fuel due to their lightness.

- It is widely used in refrigerators and kitchen utensils due to its very good heat conduction and protection properties.

- The fact that aluminum has a protective feature in contact with air can be used in the preservation of products in the food and chemical industry.

- It is used in electrical materials and systems with the principle of working with steam, since its electrical and thermal conductivity is very good.

USAGE AREAS